Місце походження: |

Китай |

Номер моделі: |

TC-2416 |

Сертифікація: |

Доступно |

Розмір |

8200*2460*3350 мм |

Регульований діапазон |

50~900 л/год |

Гірнича техніка |

|

Стан |

Новий |

Опис:

Колісна машина для зволоження бетону TC-2416 — це великогабаритний механічний маніпулятор для початкового підкріплення тунелю; Вона виготовлена з імпортної сировини та має досконале поєднання повністю гідравлічного інженерного шасі та механічного маніпулятора для напилення бетону;

Технічні характеристики:

Швидкий огляд:

Зміст проекту |

одиниця |

|

|

|

Параметри транспортного засобу |

довгий |

мм |

8200 |

широкий |

мм |

2460 |

|

високий |

мм |

3350 |

|

поводитися гідно |

килограми |

15600 |

|

|

Параметри системи прискорювача тверднення |

Модель насосу швидкодіючого агента |

|

шланговий насос |

Форми приводу |

· |

гідромотор |

|

максимальний робочий тиск |

бар |

18 |

|

регульований діапазон |

Л/г |

50~900 |

|

Об’єм бака для швидкотвердіючого агента |

Л |

1000 |

|

|

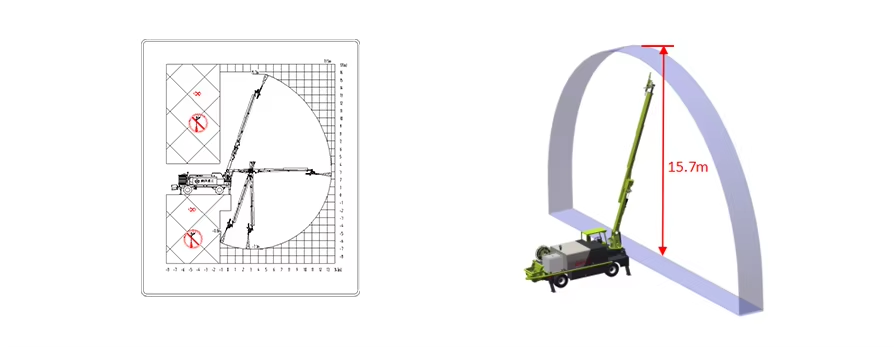

Параметри робота |

Форма конструкції рукоятки |

|

Вторинний нахил + вторинне витягування |

Форма керування |

|

співвідношення 3-з'єднання + 4-перемикач |

|

висота розпилення |

м |

16 |

|

Ширина струменя |

м |

24 |

|

Кут нахилу верхнього плеча |

° |

0~70 |

|

Верхнє плече може витягуватися |

мм |

/ |

|

Кут нахилу передпліччя |

|

Відносно верхнього плеча 0~-110 |

|

Кут повороту зап'ястя |

。 |

/ |

|

Передпліччя може витягуватися і зсуватися |

мм |

2×2300 |

|

Кут обертання сопла навколо горизонтальної осі |

° |

360 |

|

Кут вертикального осьового коливання сопла |

|

240 |

|

Сопло здійснює щіткування |

|

8×360 |

|

|

Параметри шасі |

Виробник форм |

одне |

Kapuro |

Характеристики системи шасі |

|

Гідравлічна ходова система, гнучка передача, адаптація до навантаження |

|

двигун |

|

Дизельний чотирьохциліндровий двигун |

|

можливість двигуна |

кВт |

88/96 кВт |

|

Максимальна швидкість |

км/год |

25 |

|

передача |

|

Дві вперед і одна назад |

|

мінімальний радіус повороту |

м |

11.5 |

|

максимальна прохідність по ухилу |

。 |

25 |

|

Мінімальний кліренс |

мм |

360 |

|

Передня колея |

мм |

1900 |

|

Колія задньої осі |

мм |

1900 |

|

Тип шини |

|

16 / 70-20 (спереду та ззаду) |

|

Режим живлення |

|

Привід на передні та задні колеса (повний привід) |

|

Гальмо автомобіля |

|

Повітряні гальма |

|

стоянкове гальмування |

|

Відключення гальма |

|

Спосіб повороту |

|

передній привід керма |

|

Форма ніг |

|

Вісім спереду та вісім ззаду |

|

|

Параметри системи подачі бетону [ |

Спосіб робочого приводу |

|

Тип насоса |

потужність двигуна |

кВт |

65 |

|

Напруга двигуна/частота |

V/Hz |

380/50 |

|

головний масляний насос |

|

Kawasaki K5V |

|

Теоретична максимальна продуктивність подачі бетону |

м³/годину |

30 |

|

вихідний тиск |

бар |

75 |

|

Внутрішній діаметр бетонного циліндра |

мм |

180 |

|

Діаметр трубопроводу |

мм |

150-89 |

|

Найбільша фракція заповнювача |

мм |

16 |

|

Діаметр сопла |

мм |

50 |

|

Висота завантаження бункера |

мм |

1400 |

|

Барабан кабеля |

Спосіб робочого приводу |

|

гідромотор |

Довжина кабелю |

м |

80 |

|

Спеціальний захист для кабелів |

|

Високоякісна зносостійка гума |

|

Навар |

метод керування |

|

контролер |

Режим дистанційного керування |

|

Бездротовий пульт дистанційного керування + аварійний кабель 15 м |

|

Система очищення |

Спосіб робочого приводу |

|

гідромотор |

Максимальний тиск води |

бар |

120 |

|

витрата |

L/min |

20 |

|

Функція аварійної допомоги |

Форми мотивації праці |

|

Нормальна робота здійснюється за рахунок електродвигуна, а потужність дизельного двигуна використовується для стріли, перекачування, промивки та очищення у разі раптової зупинки |

Застосування:

Цей продукт може широко використовуватися в підземних інженерних галузях, таких як водогосподарське та гідроенергетичне будівництво, шосейні та залізничні дороги, підземні фабрики, підземні військові об'єкти, а також для бетонних робіт з обприскуванням схилів різного типу.

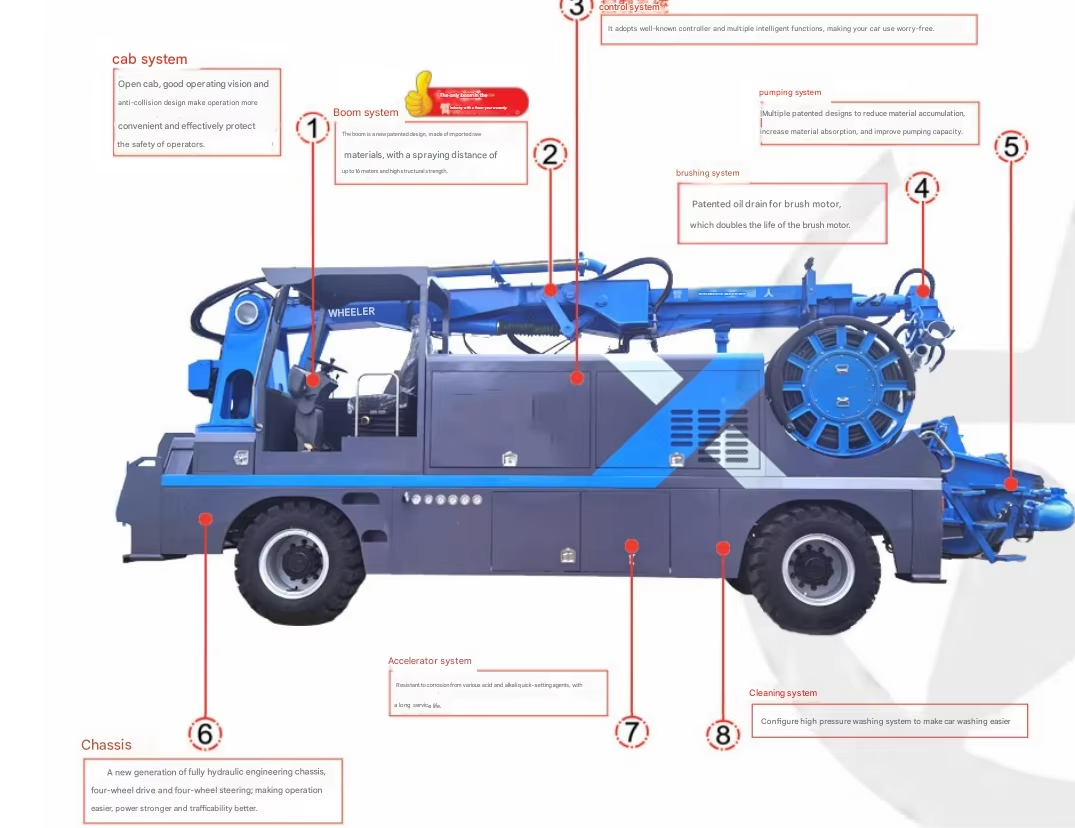

Система керування та гідравліка:

Має кілька інтелектуальних функцій, включаючи самодіагностику, сигнали тривоги рівня олії, температури олії та тиску повітря, що забезпечує підвищену надійність і спрощену експлуатацію.

Система стріли:

Завдяки абсолютно новому запатентованому дизайну та імпортним матеріалам, стріла має дальність розпилювання до 16 метрів і високу міцність конструкції.

Шасі:

Шасі останнього покоління з механічним приводом і чотирьома ведучими колесами забезпечує простоту обслуговування та експлуатації, підвищену потужність і кращу маневреність.

Система акселератора:

Високоефективний, розроблений у країні плунжерний насос для прискорювачів затвердіння забезпечує довгий термін служби та низькі експлуатаційні витрати. Завдяки унікальній запатентованій технології керування подачею прискорювача затвердіння система подачі ефективно зменшує відскок матеріалу.

Насосна система:

Оснащена великодіаметровим циліндром подачі з довгим ходом, насосна система ефективно зменшує пульсацію та засмічення трубопроводу, що робить будівництво простішим і економнішим.

Післяпродажне обслуговування

Передпродажна підтримка

Ми сподіваємося встановити гарні, довгострокові та взаємовигідні відносини з нашими клієнтами. Ми будемо розуміти

потреби клієнтів, щоб рекомендувати їм найбільш підходящі продукти.

У продажу

Вимоги клієнтів будуть на першому місці. Протягом цього періоду ми своєчасно спілкуватимемося з клієнтами, якщо у них виникнуть запитання, які потрібно уточнити.

Післяпродаж

обслуговування онлайн 24 години на добу. Коли обладнання потребує ремонту, ми можемо надати інструкції з технічного обслуговування онлайн та підтримку.

Послуги

Підземне гірничодобувне обладнання потребує регулярного технічного обслуговування для забезпечення оптимальної продуктивності та безпеки. Це може включати планові перевірки, змащення, заміну деталей. Ми можемо надати деякі набори інструментів і забезпечити постійність поставок запасних частин.

Чому саме ми

Як виробник оригінального обладнання, ми забезпечуємо підтримку протягом усього життєвого циклу кожного підземного навантажувача, проданого для ефективного функціонування шахти:

1. Простота у керуванні, простота у технічному обслуговуванні та простота у виготовленні

Обладнання враховує три основні принципи — простоту в експлуатації, зручність у технічному обслуговуванні та ефективність у ремонті на етапі проектування. Ергономічна кабіна зменшує втому оператора, оптимізує розташування ключових компонентів, скорочуючи час щоденного обслуговування на 30%, а модульна конструкція підвищує ефективність усунення несправностей на 50%. Глибоке розуміння виробником внутрішньої структури обладнання є ключовою перевагою, яку неможливо відтворити сторонньою стороною.

2. Глобальне авторитетне посвідчення кваліфікації

Ми маємо сертифікацію системи управління якістю ISO, системи управління навколишнім середовищем, системи управління охороною праці та безпекою на шахтах, що забезпечує відповідність кожного етапу — від виробництва до обслуговування — найвищим міжнародним стандартам і надає подвійний захист для дотримання вами нормативних вимог.

3. Система сервісного обслуговування від виробника

Розраховуючи на глобальну сервісну мережу, забезпечується швидка реакція та запуск процесу усунення несправностей протягом 2 годин. Складаються індивідуальні плани профілактичного обслуговування залежно від характеристик обладнання, а сертифіковані фахівці використовують спеціальне обладнання для проведення ремонтних робіт та повного капітального ремонту на місці, щоб забезпечити продуктивність обладнання з самого джерела.

4. Глибокі технічні можливості підтримки

Система дистанційної діагностики може визначити несправність за кілька секунд, а технічна команда надає рішення щодо оптимізації енергоефективності на основі реальних умов роботи шахти. Одночасно надається тривимірна галерея розбирання та інструкція, які оновлюються в режимі реального часу, щоб забезпечити синхронізацію технічних даних та оновлення обладнання.

5. Глобальний постачання оригінальних запасних частин

Оригінальні деталі постачаються протягом усього терміну експлуатації й доставляються терміново.

6. Підготовка фахівців гірничої справи

Унікальне обладнання виробника, що лежить в основі навчання логіці, охоплює стандартизовані операції, глибоку технологію технічного обслуговування та спеціальну підготовку з безпеки на шахтах, допомагаючи клієнтам збільшити виробництво обладнання на 15%, продовжити термін експлуатації на 20% та знизити рівень нещасних випадків на 90%.

7. Візуальна перевірка сценаріїв застосування

Через динамічні діаграми демонстрації робочих умов наочно показано фактичну продуктивність, ефективність технологічних зв'язків і результати оптимізації собівартості тонни обладнання в подібних гірничих умовах, забезпечуючи точну основу для інвестиційних рішень.

Остаточна цінність вибору оригінального виробника

Завдяки оригінальним знанням у сфері проектування обладнання, здатності до інтеграції глобальних ресурсів та глибокому досвіду в гірничій справі ми можемо забезпечити безшовне поєднання даних про сервісне обслуговування й роботу обладнання, що в підсумку дозволяє знизити комплексні експлуатаційні витрати клієнтів на 25%. Саме здатність створювати вартість протягом усього життєвого циклу обладнання є незамінною перевагою Tuoxing як виробника.

ЧаП

1. Хто ми такі? Наша головна офіс знаходиться в провінції Шаньдонґ, Китай. Ми — потужний виробничий підприємство. Ми дотримуємося принципів використання передових технологій, якості, чесності та прагнення до досконалості.

2. Чи надасте ви запасні частини для вашої продукції? Так, звичайно. Якщо вам потрібно, ми надамо їх разом із продукцією.

3. Яка якість вашої продукції? Ми маємо сертифікат ISO, а наша продукція відповідає національним та міжнародним стандартам. На всю продукцію надається гарантія.

4. Які умови оплати ви приймаєте? Ми приймаємо L/C, T/T та D/P тощо, T/T із 30% авансовим платежем після підписання контракту або підтвердження замовлення.