Place of Origin: |

China |

Model Number: |

KG-22G |

Certification: |

Available |

Condition |

New |

Description:

A grader is a large, efficient land leveling machine primarily used for leveling sites and shaping roads. It plays the role of a "meticulous worker" and "sculptor" in the construction machinery family, and is indispensable, especially in projects with extremely high requirements for flatness, such as highways, airports, and large plazas.

The core features of a grader are:

High-precision leveling: With its unique long blades and flexible adjustment mechanism, it can precisely control the elevation and slope of the leveled area, achieving millimeter-level leveling accuracy.

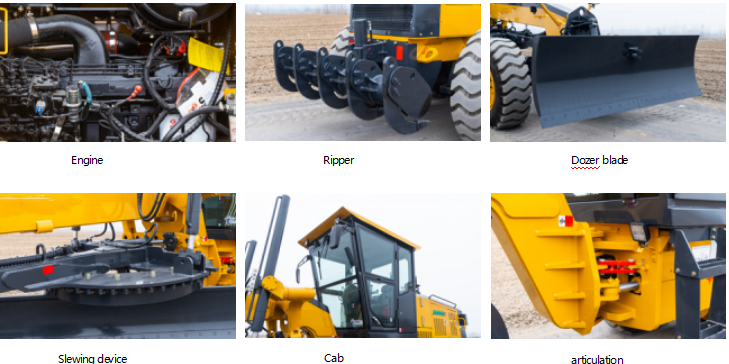

Multi-purpose: By changing different attachments, it can perform various tasks such as leveling, loosening soil, snow removal, bulldozing, and slope shaping.

High operating efficiency: On large sites, graders can perform leveling operations at high speeds, unmatched by manual labor or other machinery.

Unique "floating machine": The grader's blades are not directly and rigidly connected to the machine body, but rather connected via a multi-angle adjustable swivel and tow frame. This allows it to adapt to complex terrain and make fine adjustments.

Specifications:

Operating weight |

17000 |

kG |

Engine Brand |

Cummins |

|

Engine model |

6CTAA8.3-C215 |

|

Type |

4-stroke, direct injection, water-cooled |

|

Intake mode |

Turbocharging, air-to-air intercooling |

|

Bore × Stroke |

114*135 |

mm |

Displacement |

8.3 |

L |

Rated power |

160 |

kw |

Maximum traction force |

90 |

KN |

Maximum torque |

980 |

N.m |

Type |

Full hydraulic steering |

|

Front wheel steering angle |

±45 |

° |

Frame steering angle |

±23 |

° |

Minimum turning radius |

8200 |

mm |

Blade slewing angle |

360 |

° |

Blade length |

3660/3965/4270 |

mm |

Blade height |

635 |

mm |

Blade penetration depth |

500 |

mm |

Blade lifting height |

440 |

mm |

Max. lateral extension distance |

1900/1950 |

mm |

Total length: Standard model |

9430 |

mm |

Total length: With front blade model |

10310 |

mm |

Total length: With rear loosening attachment |

9920 |

mm |

Total length: With front blade and rear loosening attachment model |

10630 |

mm |

Front and rear wheelbase |

6260 |

mm |

Rear wheelbase |

1550 |

mm |

Height |

3400 |

mm |

Wheel track |

2155 |

mm |

Width |

2600 |

mm |

Minimum ground clearance |

430 |

mm |

Applications:

1. Highway Engineering:

Roadbed Leveling: Final leveling of the roadbed during the construction of expressways and national/provincial highways.

Road Crown Shaping: Using the tilting and rotation of a shovel, shaping the lateral slope of the road surface (road crown) to facilitate drainage.

Slope Trimming: Trimming the slopes of embankments or cuts into the designed slope.

2. Airport Construction: High-precision leveling of runways and aprons.

3. Farmland Irrigation: Large-scale farmland leveling for the construction of high-standard farmland.

4. Snow Season Operations: Snow removal at airports and on expressways after installing snowplows or snow brushes.

5. Other Fields: Site leveling for stadiums, large plazas, and industrial parks.

Competitive Advantage:

1.High work efficiency

The grader can significantly accelerate road leveling speed, greatly reducing project duration compared to traditional manual leveling methods.

2.Higher accuracy

Through a precise control system, it is possible to accurately regulate the leveling depth and width, ensuring that each leveling operation strictly meets the requirements of the design specifications.

3.Reduce labor costs

It can be equipped with a variety of auxiliary tools, adapt to road - leveling operations in various environments, and significantly reduce the operation cycle.

4.Improved security

It reduces the risk of direct manual operation, especially when handling large or heavy materials, and improves the safety of the construction site.

5.Environmental protection and energy saving

It is driven by compressed air, which reduces noise pollution and fuel

consumption, and is more in line with the concept of green environmental protection.

6.Highly adaptable

Able to adapt to different terrain conditions and construction environments, including but not limited to plains, mountains and other complex terrains.

After-sale Service

Pre-sale

We hope to establish a good, long-term and mutually beneficial relationship with our customers. We will understand

customers’demand so that recommend the most suitable products for them.

In sale

Customers’ requirements will be put in the first place. During this period, we will communicate with customers in time if they have any questions need to be confirmed.

Post-sale

24 Hours Online service. When the equipment needs repair, we can provide online maintenance guides and support.

Services

Underground mining equipment requires regular maintenance to ensure optimal performance and safety. This may involve routine inspections, lubrication, replacement of parts, We can provide some tool boxes and provide a lifetime supply of spare parts.

Why Choose Us

As an original equipment manufacturer, we provide full life cycle support for each underground loader sold to ensure efficient operation of the mine:

1. Easy to operate, easy to maintain and easy to maintain manufacturing genes

The equipment incorporates the three core principles of easy operation, convenient maintenance and efficient maintenance during the design stage. The ergonomic cockpit reduces operator fatigue, optimizes the layout of key components to shorten daily maintenance time by 30%, and the modular structure design increases the efficiency of fault repair by 50%. This deep understanding of the underlying structure of the equipment by the manufacturer is a core advantage that cannot be replicated by a third party.

2. Global authoritative qualification certification guarantee

We hold ISO quality management system, environmental management system, occupational health and safety system and mine safety certification to ensure that every link from production to service meets the highest international standards, providing double protection for your compliance operation.

3. Manufacturer direct service system

Relying on the global service network to provide rapid response and start the fault handling process within 2 hours. Customize preventive maintenance plans based on equipment characteristics, and the original certified technicians use special tools to perform on-site repairs and overhaul services to ensure equipment performance from the source.

4. In-depth technical support capabilities

The remote diagnosis system can locate faults in seconds, and the technical team provides energy efficiency optimization solutions based on the actual working conditions of the mine. Simultaneously provide real-time updated three-dimensional disassembly gallery and operation manual to ensure that technical data and equipment iterations are synchronized.

5. Global supply of original spare parts

Pure original parts are directly supplied for life and delivered urgently.

6. Training of mining professionals

The manufacturer's unique equipment underlying logic training covers standardized operations, in-depth maintenance technology and special training for mine safety, helping customers increase equipment output by 15%, extend service life by 20%, and reduce safety accident rate by 90%.

7. Visual application scenario verification

Through dynamic working condition demonstration diagrams, the actual production efficiency, process connection efficiency and ton cost optimization results of the equipment under similar mine conditions are intuitively presented, providing accurate basis for investment decisions.

The ultimate value of choosing an original manufacturer

Relying on the original knowledge of equipment design, global resource integration capabilities and vertical field experience in mining, we can achieve seamless integration of service data and equipment operation, and ultimately reduce the comprehensive operating costs of customers by 25%. This ability to create value throughout the entire life cycle of the equipment is The irreplaceable advantage as a manufacturer.

FAQ

1. Who are we? Our headquarter is located in Shandong, China. Our strength manufacturing plant. We adhere to the leading technology, quality, integrity-based, the pursuit of excellence for the purpose.

2.Will you provide some wearing parts of your products? Yes, of course.If you need, we will provide with the products.

3.How is the quality of your products? We have been approved of ISO, and our products accord with national and international standards.Our products all contain warranty.

4.What payments term do you accept? We accept L/C,T/T and D/P etc,T/T goes with 30% advanced payment after signing contract or order confirmation.